Product Upgrades

Improved and Redesigned Parts

Copar is dedicated to providing the highest quality state of the art electronic controls and products. Over the years the Copar engineering group has made several updates and upgrades to many different parts of our control systems. Copar is always looking for ways to improve and implement new and exiting features to our existing control units whether it would be on the corrugating side or the finishing side of the corrugating process.

As Copar is redesigning our current products we take suggestions and information from our customers so that we can make the corrugating process more simplified and streamlined to our customers needs.

Bridge Validation Spray Assembly

Benefits:

· Improved closed loop bridge validation process.

· Automatic water volume adjustment during a bridge validation spray sequence.

Features:

· Dynamic water volume adjustments based on the single facer speed.

· One, two, or three nozzles are used depending on the machine velocity

· Improved thermal isolation between the tips and the machine frame.

· Reduced water temperature will result in more consistent water mark detection

Cleaning Kits for Heating Section Sensors

Air Cleaning Kit:

· The new kit configuration includes two air filters and a coalescing filter to remove oil and water

· The air solenoid periodically clears debris off the sensor

Redesigned Sensor Hoods:

· The new heating section hoods fully surround the sensor, shielding the sensor head from dust and debris

· Clean air is aimed directly at the sensor surface to maximize its effectiveness

Temperature Sensor Upgrade Packages

Benefits:

· Improved accuracy over the entire temperature range

· The electronics are separated from the sensor head, which makes the sensor less prone to machine vibrations. Previous sensors had a fixed calibration that could drift with machine vibration over time

Features:

· High Thermal Stability. The new digital technology can tolerate ambient temperatures as high as 248° F (120° C)

· Greater Mounting Flexibility. With a 15:1 spot size ratio, the sensor can be mounted in more confined spaces and further away from the paper if required

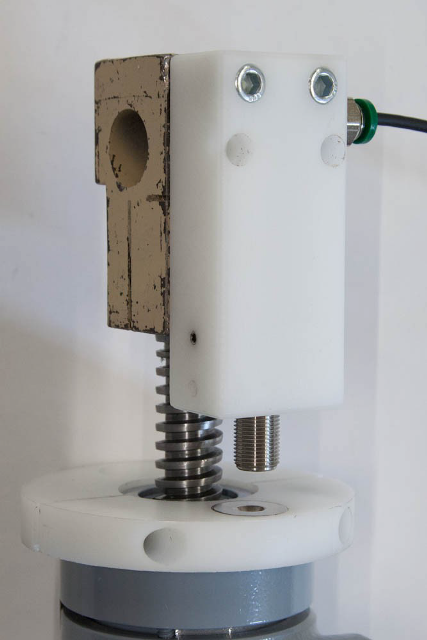

United Metering Roll Sensor Upgrades

Benefits:

The new Metering Roll Gap Sensor has less components to install. This kit is a direct replacement for existing Copar United Metering Roll Gap Sensors that a plant may have.

Features:

· New, Robust Design

· Improved Accuracy

· Simple Three Wire Connection with No Amplifier

· Simplifies Maintenance

· Low Cost

· Easy Installation

Booster Pump Kit

Benefits:

· A facility’s low water supply pressure problem is eliminated

· Improved Sync Splice reliability by maintaining a constant pressure, even when the water supply spikes

Features:

· Standard 24VDC Booster Pump provides a safe environment

· 115VAC kits are available (only if required)

· Provides a constant 35PSI (2.4 bar) during pressure spikes

· The pump turns on only if the system detects low pressure

· Designed specifically for water volume requirements of the Copar systems

· Kit utilizes off the shelf parts

· Easy installation