Warp Wacker

Benefits and Features

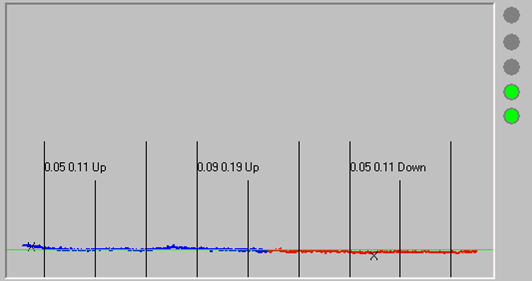

- Provides full time, closed loop corrections

- Reduce waste due to warped board

- Reduce operator time correcting warped conditions

- Increase production speed since flat board is maintained

- Increase finishing department output with fewer jam ups on high speed equipment

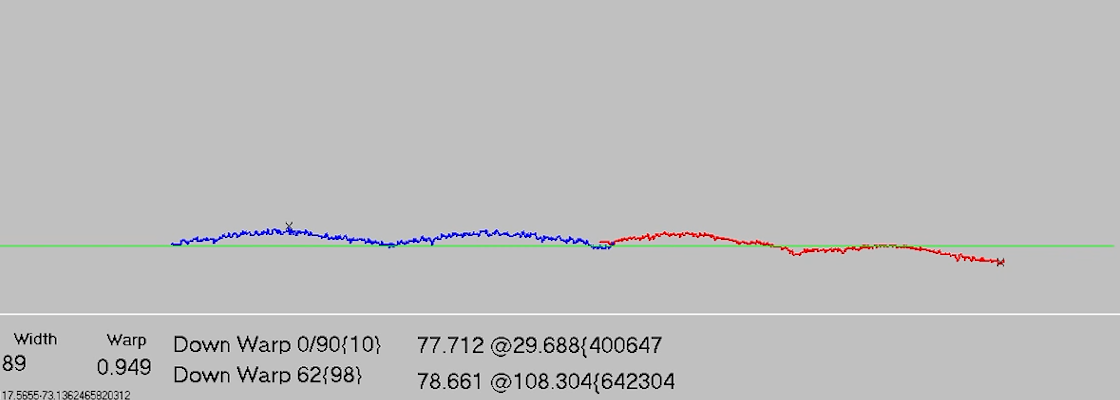

- Real time board monitoring is displayed for troubleshooting

- 100% Solid State, No Moving Parts or Motors

- No onsite calibration needed, ever….

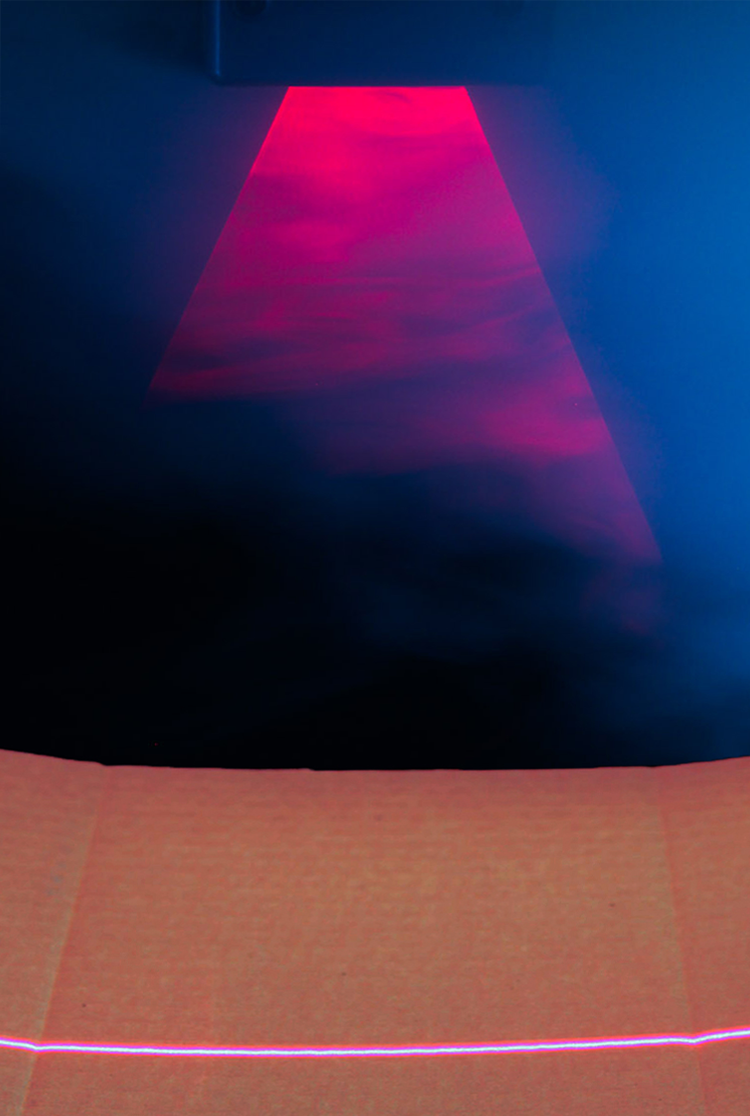

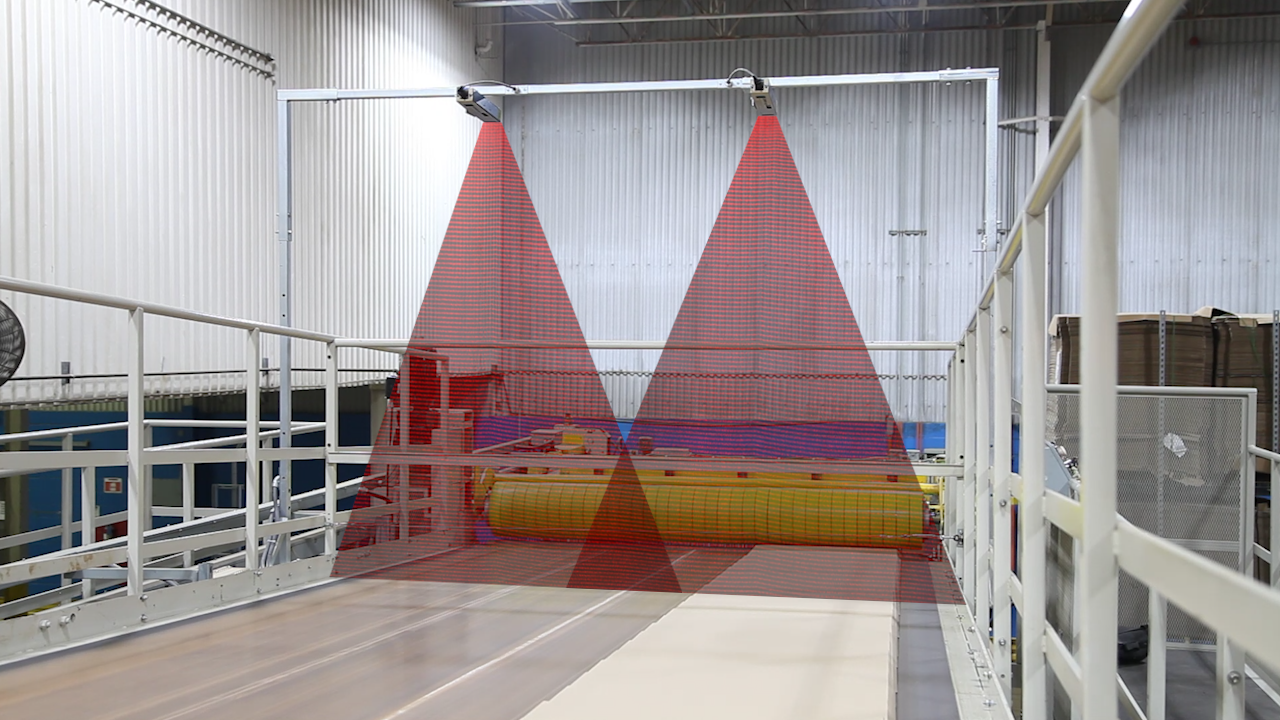

The Warp Wacker is an optional feature that integrates with the Copar Quality Master system. Warp Wacker continually monitors corrugated sheets on the stacker conveyor for warped conditions, and adjusts the machine automatically until flat board is produced.

With only two lasers, 1200 individual measurements can be made across machines up to 110 inches (2,9 m) wide. This ensures accurate measurements, while utilizing simple integration into existing Copar Wet End Corrugator Control system. The Warp Wacker is the #1 tool in corrugator warp control on the market.