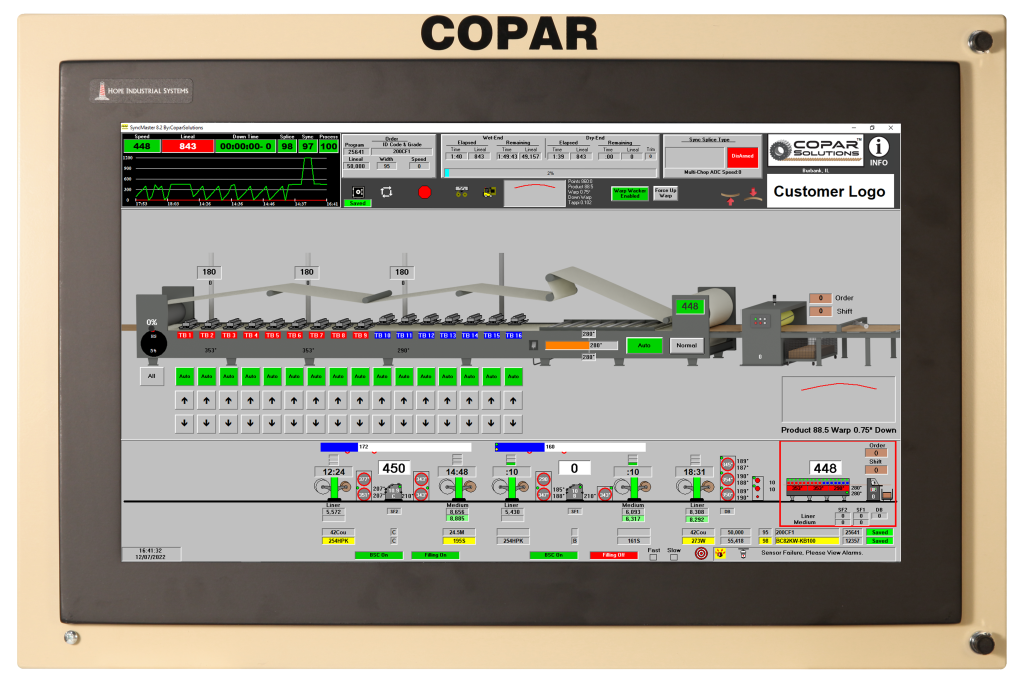

Process Control

Quality Master CTC

The Quality Master CTC (Copar Technical Control) will help your operators produce stronger board with a better printing surface by standardizing and automating process variables. As production speed changes and new rolls are spliced into, the system applies grade specific adjustments in several ways:

- Paper Temperatures: Preheater and preconditioner wrap arms adjust to maintain center-lined targets.

- Heating Section: Individual sections raise or lower to maintain the target temperature.

The heating section entrance wrap arm position can be added to the grade recipe (optional). - Starch gaps with speed curves: Meter gaps adjust to the target for each grade. Highly customizable curves

help reduce starch consumption when the machine speed increases. - Web Tension (optional): Manage directional warp by controlling a web tension system.

- Heating section steam throttling (optional): Steam chest temperatures can be changed for certain grades,

such as preprint or lightweights. - Closed-loop Warp Detection/Correction (optional): Warp is measured by lasers mounted above the stacker.

Automatic warp offsets override heating section and/or preheater temperature goals

Center-lined Operations

Corrugator performance becomes more repeatable by removing variance from operator to operator and from shift to shift. The most effective way to ensure center-lined goals are achieved is through automation. With Quality Master, grade “recipes” are saved for each grade, and automatically recalled the next time the grade is run.

Consistency

Consistency from the start to finish of an order is important for the customer. With the Quality Master, you will notice more consistent, flat sheets across the plant floor. Automation helps produce quality sheets throughout the order at full production speed, during machine slow downs for splices or setup changes, and by compensating for roll moisture and temperature variance after a splice.

Increased Production

Copar’s P.O.P. software optimizes the corrugator speed, accounting for heat that is not being fully utilized. If certain conditions are met, the machine will increase speed gradually until it hits a speed limiting condition, such as maximum knife cut speed. The plant will benefit with a more efficient use of available heat energy while production output will increase.

PLC Processing

Designed for the Environment

- Allen Bradley Compact Logix PLC processors and I/O

modules are designed and tested for durability and longevity in

industrial environments.

Easy Software Updates

- Included with the system are free software updates for

previously purchased options. - Copar does not charge fees for performance updates for

existing equipment. - Updates can often be installed remotely via a VPN Network

connection to avoid on-site service labor charges.

“Off the Shelf” Parts.

- The Quality Master uses Allen Bradley PLCs, which are

readily available worldwide. - Copar maintains a full inventory of PLCs and other off the

shelf components. - The plant’s spare part inventory can be kept to a minimum

since these items are available for same day shipping and/or

same day receiving if requested.