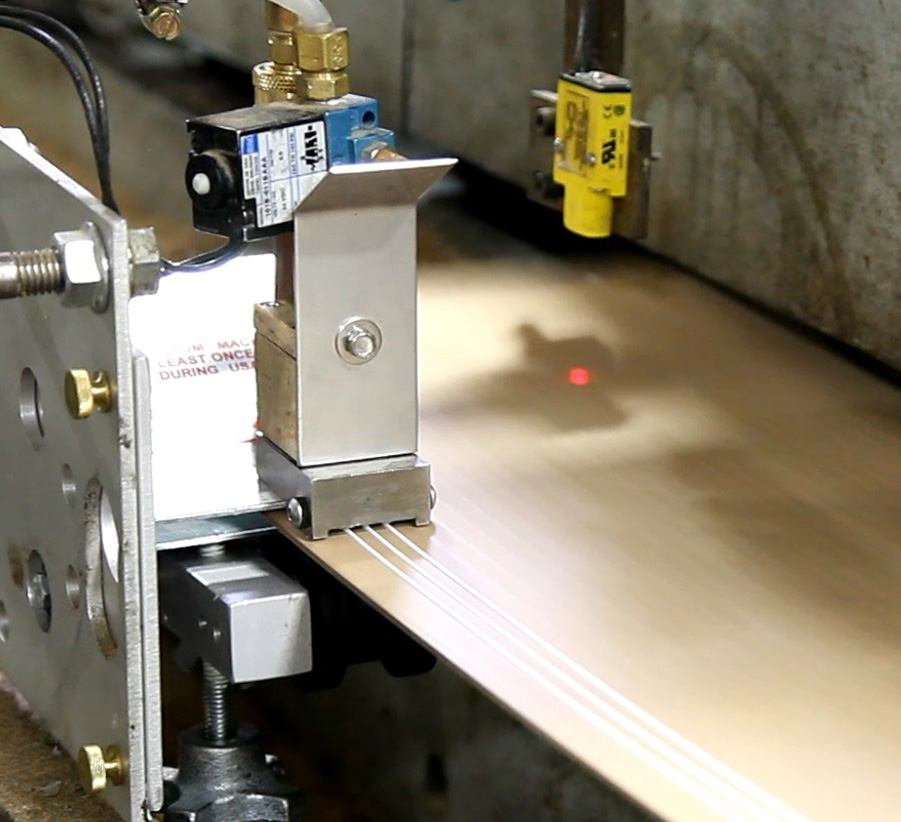

Glue System for Converting Machines

Glue System Controller

Copar’s Digital Glue System provides greater flexibility and glue volume control, reduces the amount of glue required, and reduces tack time. The set-up is operator friendly and requires very little work.

Copar uses a three-way valve that has both glue and water feeding the extruder. The valve can be easily switched for quick and easy clean-up. This method reduces end-of-shift or end-of-day clean-up time to seconds.

Benefits

· Glue flow stops automatically when the machine stops, even when a carton stops under the glue extruder

· The pattern position is maintained constant regardless of speed changes between 0 and 1800 fpm (550 mpm)

· The DGSC eliminates common problems such as slinging of glue and having trim waste scrape glue off the wheel surface

· Minimizes the problem of boxes sticking together on the inside or extruded glue outside, preventing problems with customers automatic packing machinery

· The DGSC requires less cleanup time. It reduces end-of-shift or end-of-day cleanup time to seconds

· There are no parts to remove or soak overnight

Features

· Stitch Gluing

· Next Order Entry

· Optional Non-Contact Extrusion Heads

· Digital Pattern Entry

· Solid State Circuitry Design

· Fewer Components

· Flexible Programming

· Overload Protection On All Valve Outputs

· Data Retention During Power Outages

· Capable Of Precise Adjustments During Operation

· Inputs And Outputs Separated

· Configuration Parameters Entered Digitally