Production at a glance

Keep Green on the screen!

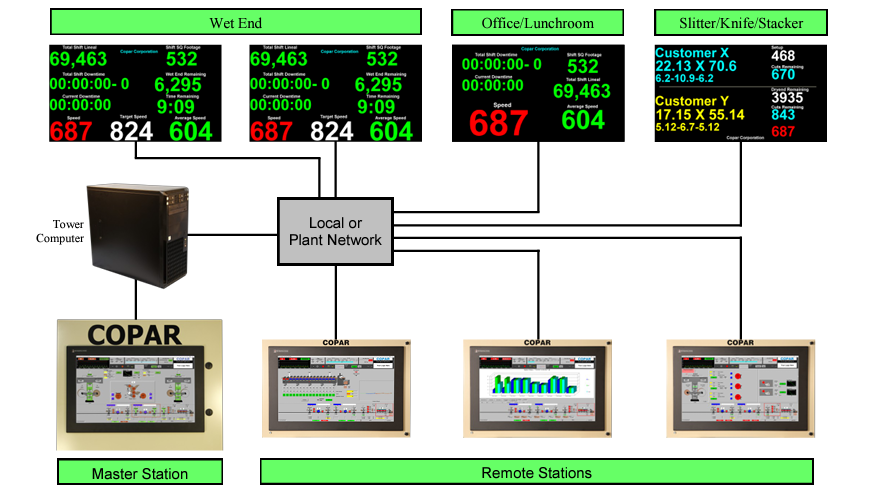

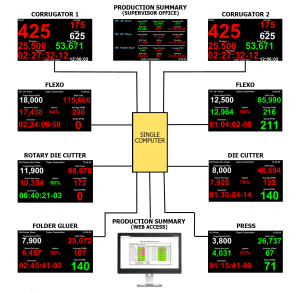

Copar offers a variety display options to help operators and manager keep track of key production statistics throughout the day.

Simple, but effective, Copar displays take advantage of colors to convey production target achievements and for order change ready status.